ELECTRONIC ENGINEERING AND MANUFACTURING SERVICES

SOLUCIONES COMPLETAS.

NOSOTROS TE GUIAMOS.

Desde diseño y servicios de ingeniería, hasta fabricación en serie, proporcionamos servicios de alto valor añadido en todo el ciclo de vida del producto, impulsando el crecimiento de nuestros clientes.

Expertos en sectores tecnológicamente avanzados con productos de alta complejidad, ofrecemos elevadas prestaciones técnicas, soluciones de fabricación innovadoras, dedicación y sólido nivel de servicio, orientando a nuestros clientes en sus proyectos.

¿POR QUÉ ELEGIRNOS?

Calidad

En búsqueda continua de la perfección, nos mantenemos en una evolución constante, mejorando nuestras capacidades y habilidades, dinamizando nuestros procesos, innovando en soluciones e invirtiendo en las más avanzadas tecnologías. Nuestra marca es sinónimo de calidad.

Expertos

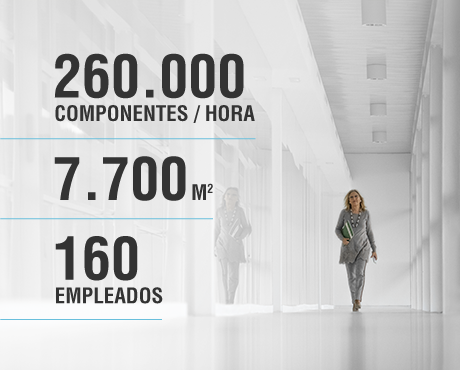

Con más de 40 años de experiencia, conocemos en detalle el pasado y los retos futuros del mercado electrónico. Este conocimiento nos permite adelantarnos y prever oportunidades y soluciones que transmitimos a nuestros clientes.

Value Added Services

En un mundo disruptivo con cambios acelerados es necesario contar con profesionales altamente especializados. Nuestro cualificado equipo proporciona al cliente servicios en electrónica de alto valor añadido, con innovación, eficacia y precisión.

Full Solutions

Desde la definición de especificaciones técnicas para el diseño, hasta la fabricación en serie. Proporcionamos un servicio integral en toda la vida del proyecto. Tú decides hasta dónde quieres que te ayudemos.

Centrados en el Cliente

Somos una extensión del cliente. Proveemos del soporte que necesitan, cuando lo necesitan. Nos consideramos un partner estratégico con dedicación, transparencia y honestidad, en quien confiar para alcanzar tus objetivos.

SpainSkills 2024

Enhorabuena a nuestro compañero Eduardo Losada por la medalla de Oro en electrónica en las Olimpiadas de FP Spainskills 2024. [...]

Patrocinadores del Club Ciclista Azkoien

Nos estrenamos como patrocinadores del Club Ciclista Azkoien. Desde FALCÓN ELECTRÓNICA os animamos a que participéis en los recorridos que se realiza [...]

Visita alumnos del Grado de Ingeniería Electrónica de la UPNA

¡Marzo está siendo el mes de la formación por excelencia! Nos visitan chicos y chicas estudiantes de Grado de Ingeniería en Tecnologías Industriales [...]

Semana de la Electrónica 2024

El director de nuestro Centro de Ingeniería ELANG ENGINEERING, Kiko Rozas junto con Javier Irigaray, uno de nuestros ingenieros expertos en diseño el [...]